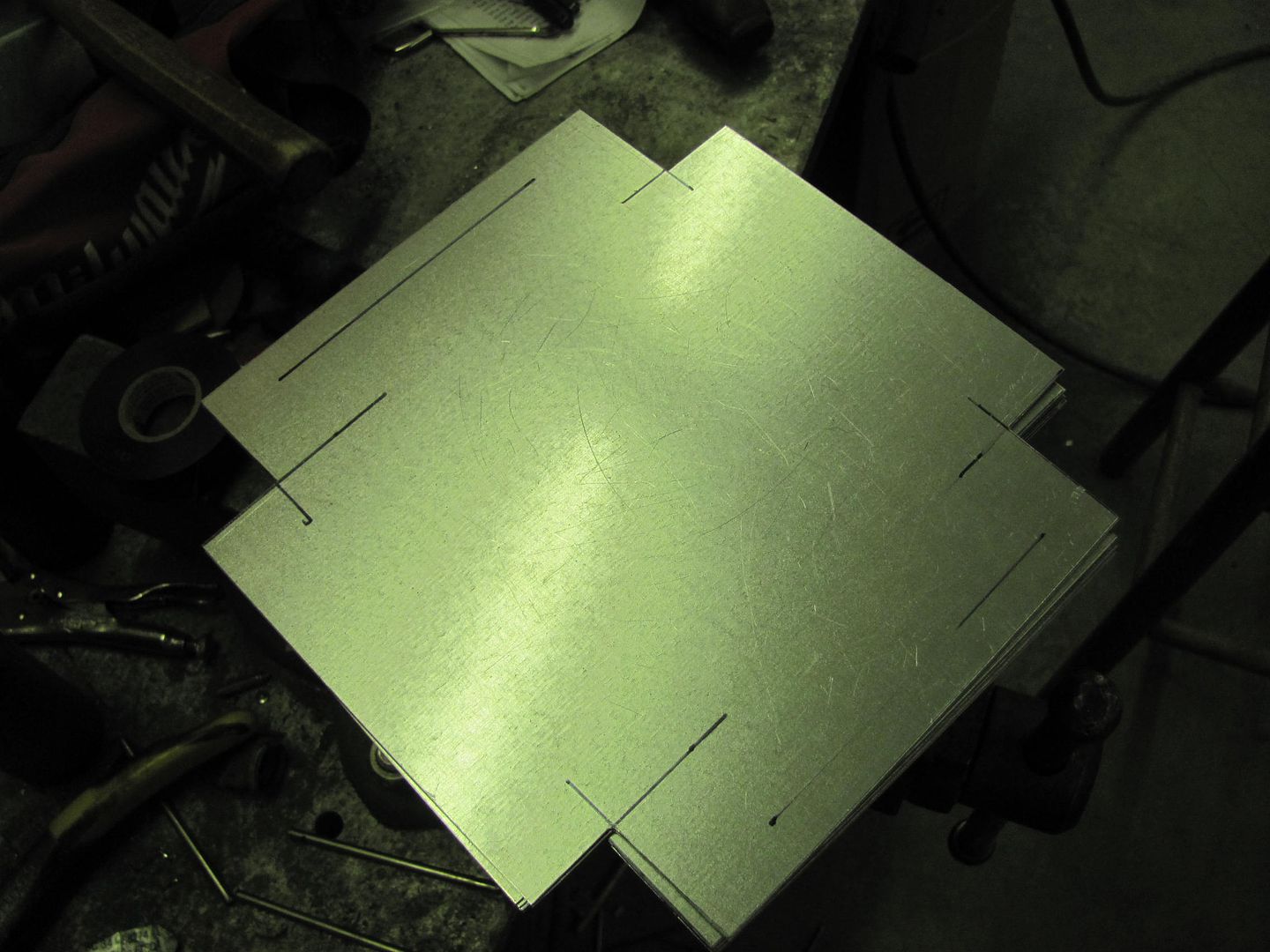

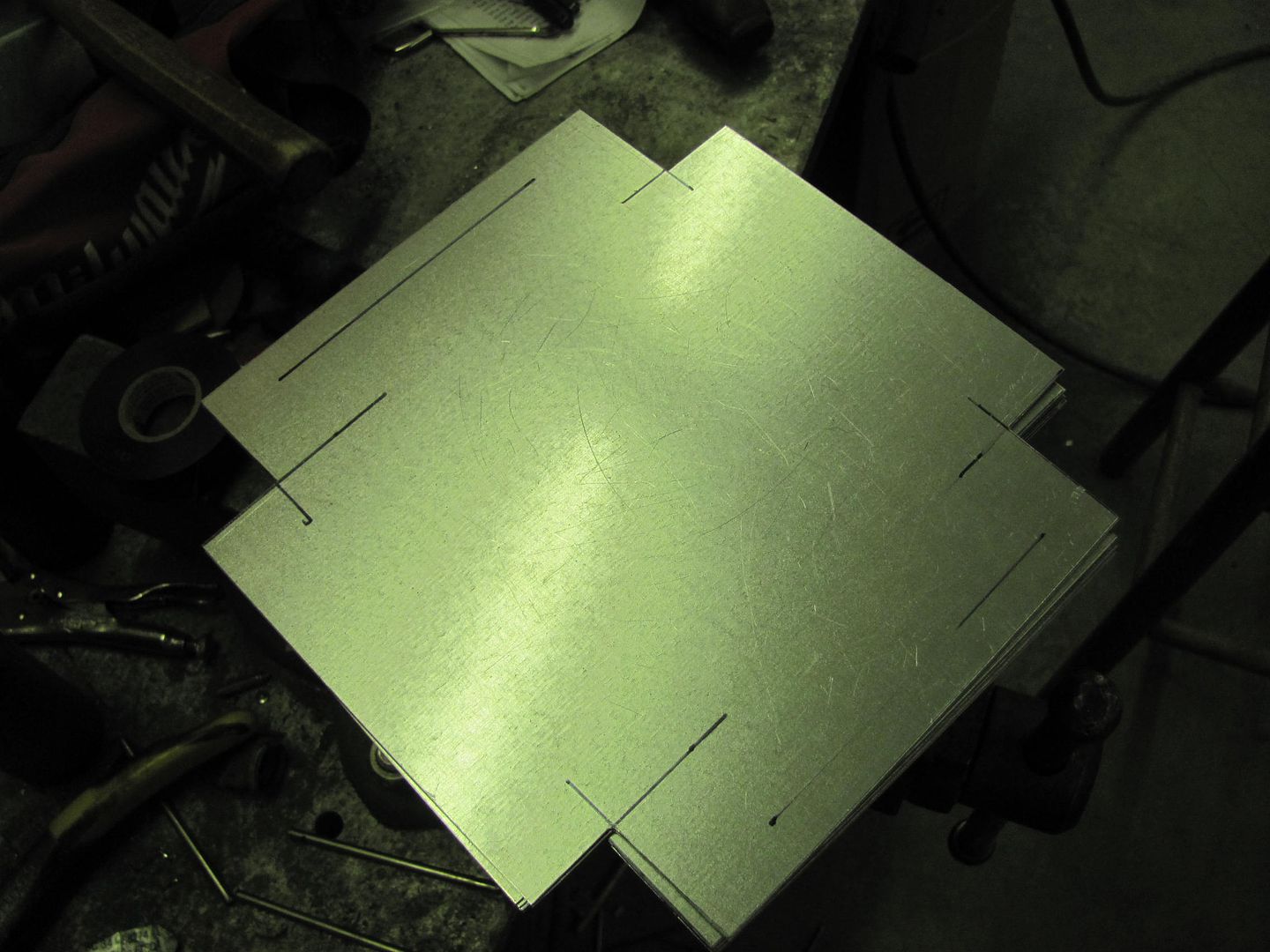

Here's a nifty trick I used in the shop recently, perhaps someone can make use of it on their own projects.. We had some standoff "hat sections" to fabricate a couple weeks back, and needed multiple quantities.

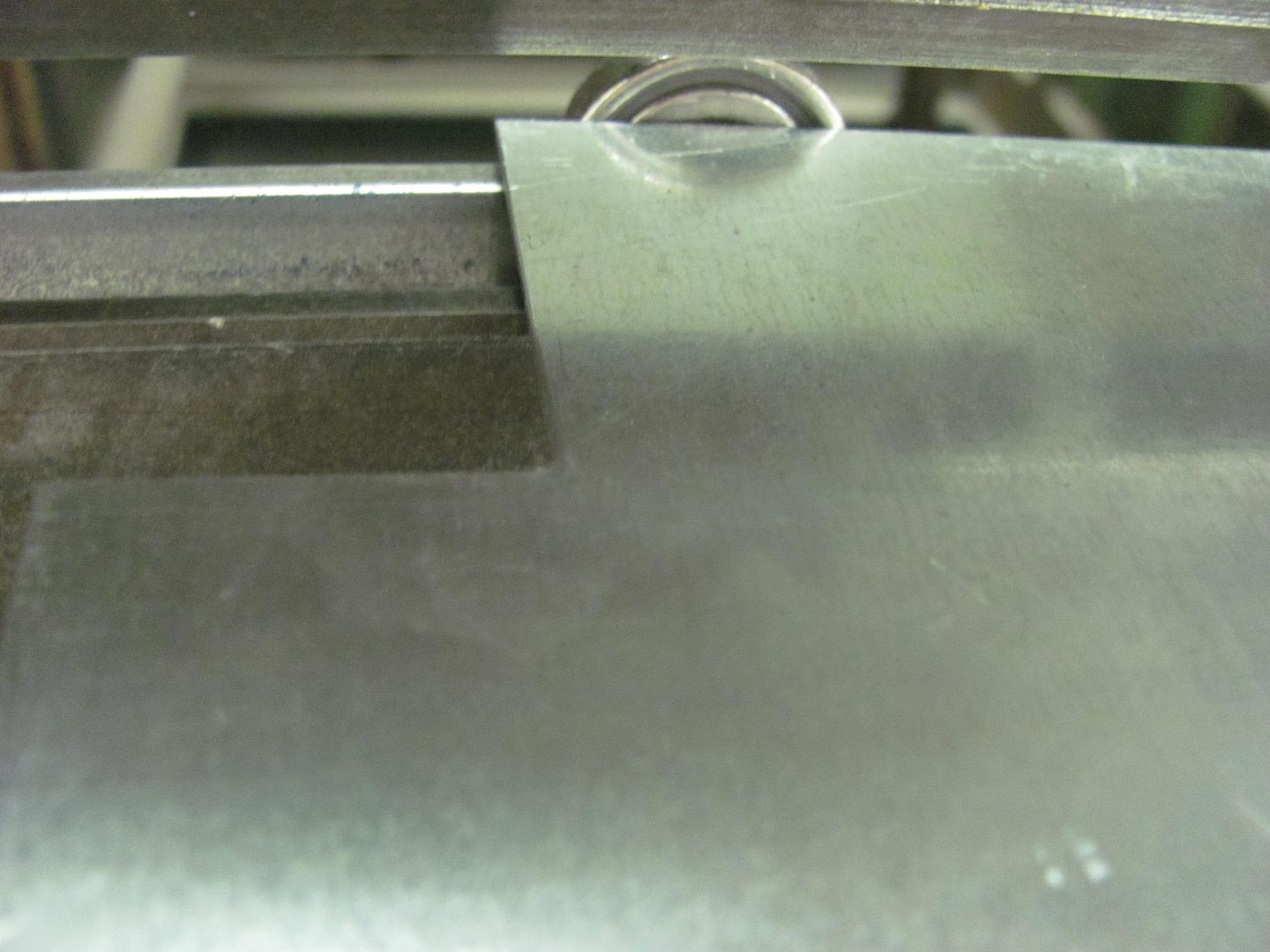

One of the bends was to form a 1/2" flange, so the press brake was used with a 1" wide die...

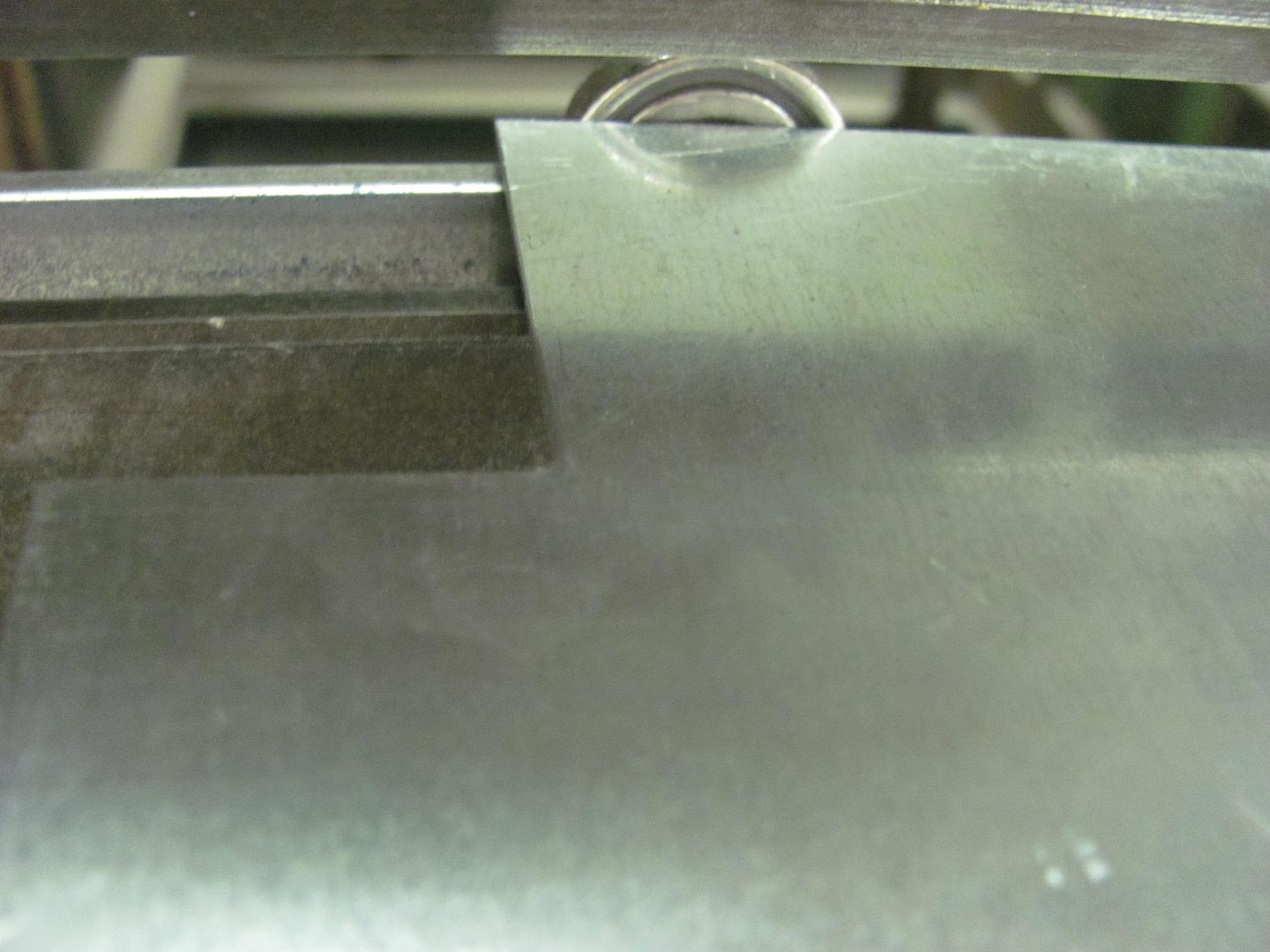

Using some rare earth magnets placed on the back side of the lower die to act as a backstop.... much easier set up than fooling with the Diacro's built in backstop..

The bonus was it pulled the galvanized sheet metal in tightly toward the magnet, a self-loading if you will...

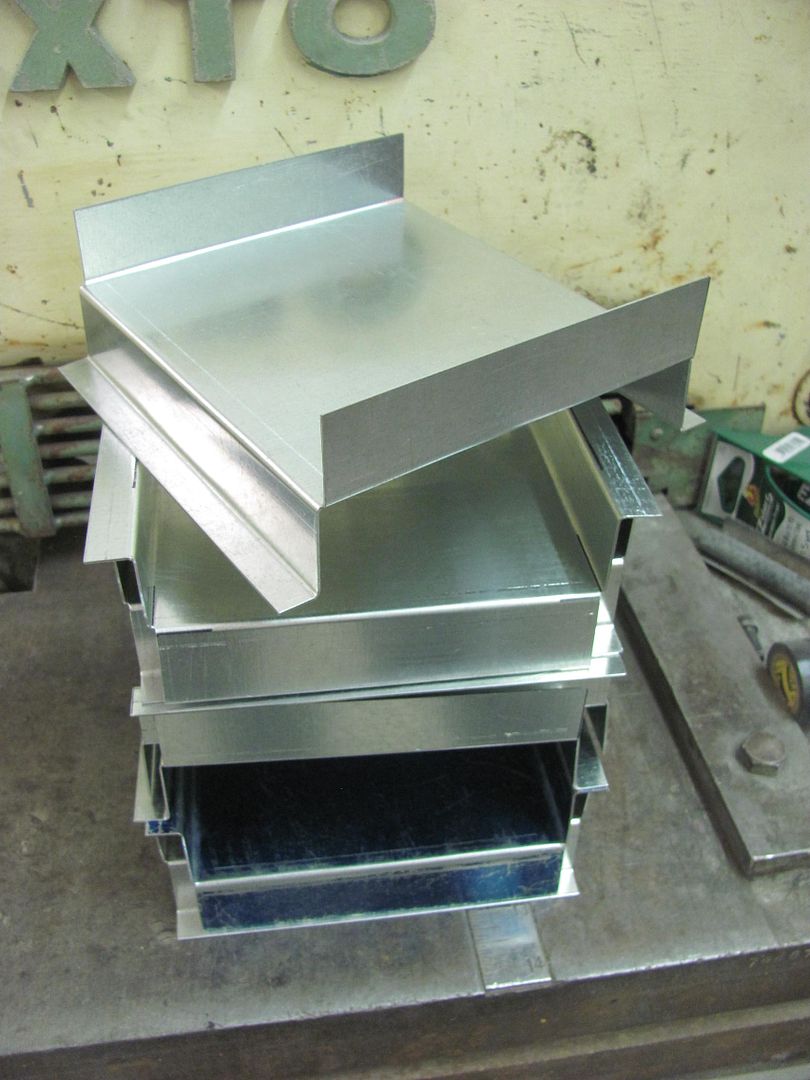

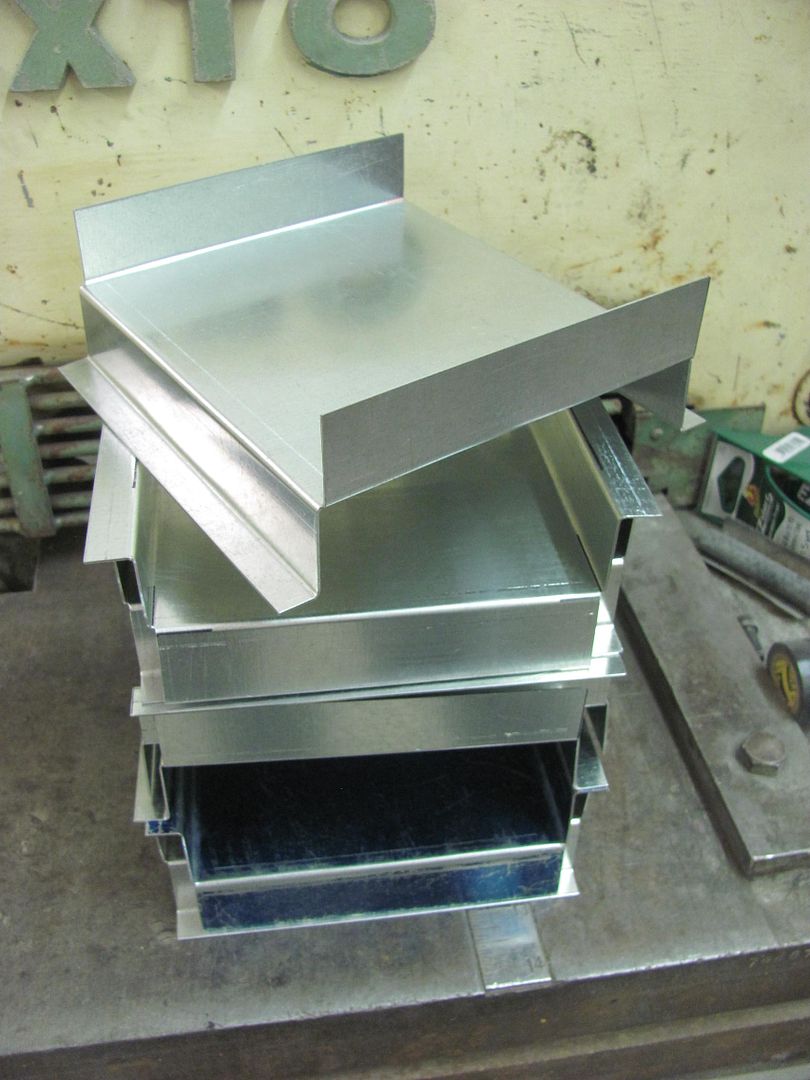

Some of the finished products...

One of the bends was to form a 1/2" flange, so the press brake was used with a 1" wide die...

Using some rare earth magnets placed on the back side of the lower die to act as a backstop.... much easier set up than fooling with the Diacro's built in backstop..

The bonus was it pulled the galvanized sheet metal in tightly toward the magnet, a self-loading if you will...

Some of the finished products...

Comment