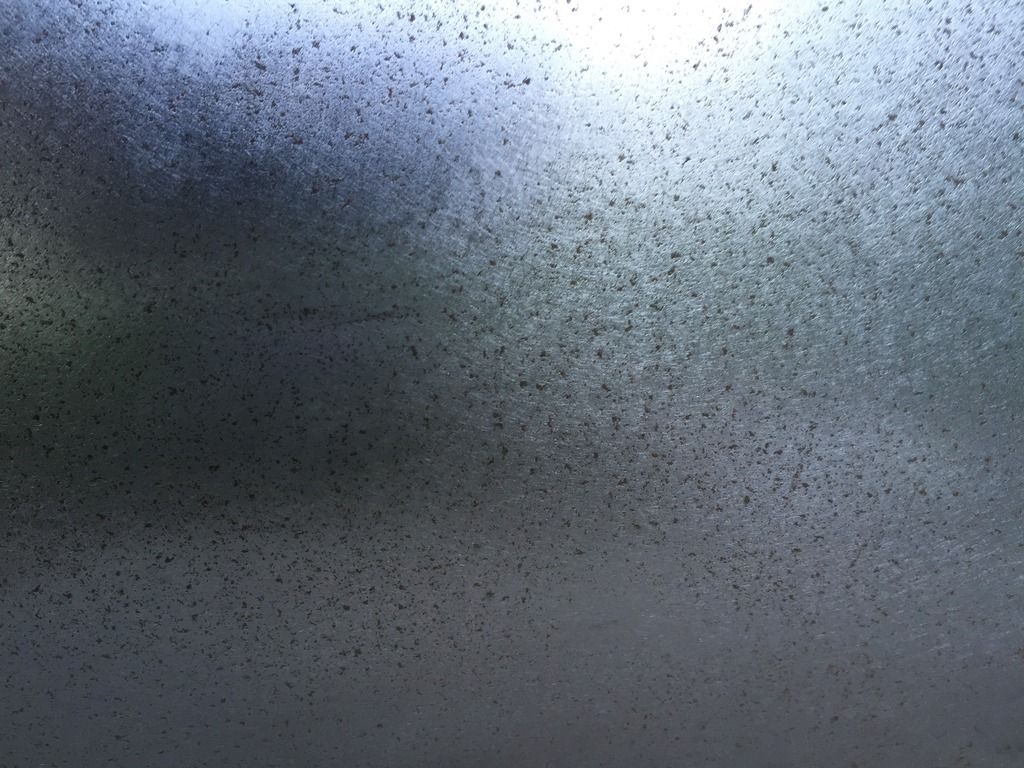

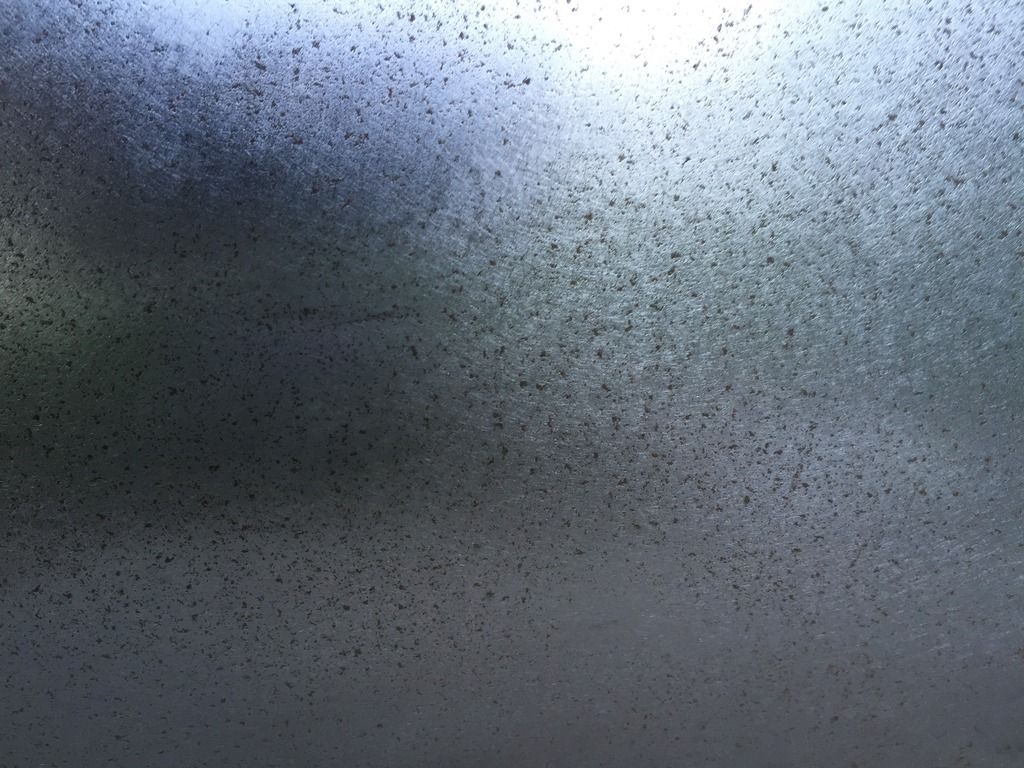

In an an attempt to find good metal to determine the extent of lower qtr patch I started my first ever battle with decades of exposed metal. Apparently someone stripped this car in an attempt to do body work years ago and never finished it. After 10 hours of hard sanding and 2 application of naval jelly rubbed in with steel wool I'm starting to make progress. There is still some pitting that needs more work. My current plan is to continue with the naval jelly and DA. I saw guys use hand held blaster to spot blast the remaining pits what are your thoughts on this?

Thanks

Rocky

Thanks

Rocky

Roof last please,you will have your technique mastered by then.

Roof last please,you will have your technique mastered by then.

Comment